Industry 4.0 and new technologies

Industry 4.0 is a term we hear quite often these days. In simple words, it denotes the current trend of automation and data exchange in production technologies.

In fact, in general terms, the industrial revolution refers to a radical change that first occurred in England in the 1780s. It introduces the power of production to the entire society, completely changing the structure of the economy by increasing and multiplying labor, goods and services. A large number of factories appeared, equipped with machinery, producing large quantities of products at low cost.

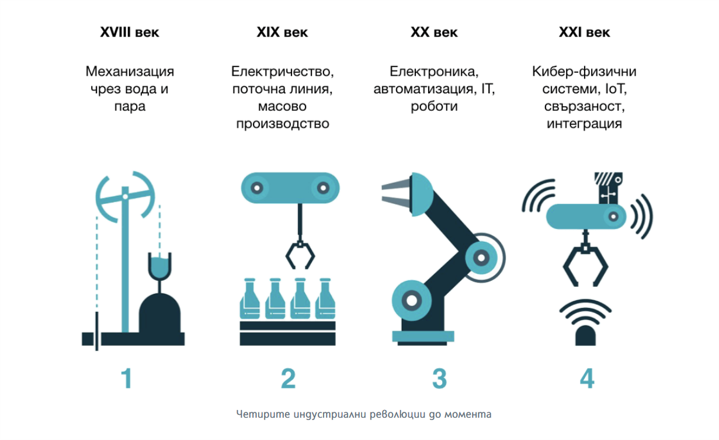

The first 3 industrial revolutions have transformed today's modern society. With each of these advances—the steam engine, the years of science and mass production, and the rise of digital technology—the world around us is fundamentally changed.

Source: https://toest.bg/zakusnyavashata-digitalna-transformatsiya-na-industriyata-u-nas/.

Now, all this is happening again for the fourth time with the difference that this time the revolution is driven by cloud services, social media, mobile technology, Internet of Things (IoT) and Artificial Intelligence (AI), as well as increasing computing power and data. The main idea behind Industry 4.0 is the creation of "smart factories" in which machines and devices are networked, communicate with each other and make autonomous decisions based on real-time data analysis. Here are some of the main advantages that clearly indicate the need for the fourth industrial revolution and the technologies associated with it:

- It is inherently a decentralized system

- It leads to innovation in the economy

- Creates new products

- Increases productivity

- Creates new business models

- It puts people at the center of production

- Puts customers at the center of all activities

How are things in Bulgaria?

On August 30, 2017, the Council of Ministers approved "Concept for digital transformation of Bulgarian industry (Industry 4.0)" with Protocol Decision No. 37, as a basis for developing a Strategy for Bulgaria's participation in the Fourth Industrial Revolution. The purpose of the current Concept is to create prerequisites for modernization, automation and competitive positioning of the Bulgarian economy in the medium to long term (2017-2030). The vision outlined in the Concept is for Bulgaria to be recognized as a regional center of the digital economy by 2030 through the implementation of products, technologies, business models and processes from Industry 4.0.

What happens in reality

According to a Fortune Business Insights Market Research Report, Bulgaria is among the countries with the lowest Industry 4.0 market share in Europe, with this share expected to reach only 0.5% in 2029, while the EU average is 5 ,4%. A Statista report from April 2023 shows that Bulgaria has the lowest share of Industry 4.0 revenues in Europe, accounting for just 0.1% of GDP in 2019, compared to the EU average of 0. 7%. The catch-up and chaotic nature of the implementation of the Digital Transformation Concept, whose implementation status is unclear at the moment, stifles the progress of Bulgarian business in many directions.

Significant European studies such as Report on the Digital Decade 2023., point out that the level of digitalization of business in Bulgaria is well below the EU average and therefore remains far from the set goal of the Digital Decade. For example, the report shows that only 47% of SMEs have at least a basic level of digital intensity, compared to an EU average of 69% and a target of 90%. When it comes to digital skills, Bulgaria makes a moderate contribution to the goal of The digital decade in terms of digital skills. For example, only 31% of people have at least basic digital skills, which is below the EU average of 54% and at the same time the lowest in the EU. The gap with the EU average is also very high when it comes to the level of people with above basic digital skills too: just 8% compared to 26% at EU level. However, not everything looks so negative and in fact Bulgaria is not only in the role of a catch-up country. In the field of "Digital infrastructures", for example, our country performs very well in terms of VHCN (Very High Capacity Network) coverage, which reaches 86% and is above the EU average of 73%. Likewise, FTTP (Fiber To The Premises) coverage is 86% – well above the EU average of 56%.

Partly due to the political uncertainty in the country in the last few years, the initiative for digitalization of the Bulgarian industry and the implementation of Industry 4.0 concepts and technologies in most cases is carried out on a private basis rather than a universal approach. However, there are also good examples of progress in different sectors, such as furniture production for example. We are proud that in our own membership ranks featuring innovators such as SIVIKO, Bader Bulgaria, Husqvarna Ruse EOOD, Bullitt Engineering J.S.C. and SL Industries Ltd, who not only implement, but also create innovative Industry 4.0 solutions and products.

The role of education

It is not surprising that education is key here as well, and the Ruse Chamber of Commerce and Industry is committed to the idea of a knowledge economy, and topics such as Industry 4.0 and Business Digitization are no stranger to it. In this regard, we are carrying out three significant initiatives with which we also make our contribution in these areas:

"Digital Twin - Digital twins for intelligent production" is a project that we launched at the beginning of this year within the framework of the Erasmus+ program. Virtualization of industrial systems will be the most commonly used way to design, test and maintain machines, according to the guidelines of Industry 4.0. This will lead to a new way of thinking that will replace the existing industrial workflow in a number of aspects. Taking this into consideration, the industry will need a new technician profile that will need to be able to integrate traditional skills in industrial automation with new competencies around virtualization and digital twin systems. In this way, a better qualified workforce will be provided, which in turn will improve and facilitate the work processes in the respective business. What else can you expect from the Digital Twin project? We invite you to learn here.

"BE-Digital - Alliance to promote innovation in business and education through digital supply chains" is an Erasmus+ project that focuses on the development of specialized courses in four thematic areas

- Automated Guided Vehicles (AGVs)

- Internet of Things (IoT)

- Data Analytics and Big Data (including Blockchain)

- Augmented and Virtual Reality (AR/VR)

The project aims to promote: the integration of disruptive digital supply chain technologies into higher education and VET curricula to address skills mismatches, and (ii) transformation of traditional supply chain business models to digital and sustainable ones . The expected results of the project include a freely accessible educational program with gamified elements (including in Bulgarian), which will provide quality training in the mentioned topics. We invite you to learn more about the Be-Digital project here.

Project "DTAM - Digital Transformation in Advanced Manufacturing Systems" ended at the beginning of 2024. year. Manufacturing SMEs increasingly need adequately trained technicians with digital competences, and the project supports the solution of this particular problem. The following freely available tools are available and we encourage you to use them:

- Digital Transformation Competency Index: indicates the necessary and appropriate competences for vocational training. Available in English only.

- The DTAM training course: aimed at understanding key foundational technologies in the main areas of Industry 4.0 such as Big Data, Machine Learning, Smart Sensors, Cyber Security and a special module on Transversal Skills.

- Guide for Trainers. Available in English only.

- A digital self-assessment tool: allows diagnostics of your soft and hard skills.

- A learning platform: an interactive multilingual platform where you will find the entire DTAM training course.

You can learn more about the DTAM project here.

The entry of Industry 4.0 into the working processes of businesses in Bulgaria, the way we work, the way we learn and generally perceive the meaning of this complex term is something we are still witnessing. This is because in our country the process is happening at a very slow pace, but there are also steps in the right direction. In order to strengthen this process, a centralized, coordinated and systematic policy is needed, supported both at the national level, but especially at the local level by the main stakeholders in the process, namely the representatives of education and business, as well as the local government. That is why RTIK continues its efforts in this area and will continue to provide the necessary impetus, spark and podium in ensuring a better and modern business climate. We invite you to follow the section regularly "Events", so you don't miss important events we plan to support business, as well as other interesting topics.